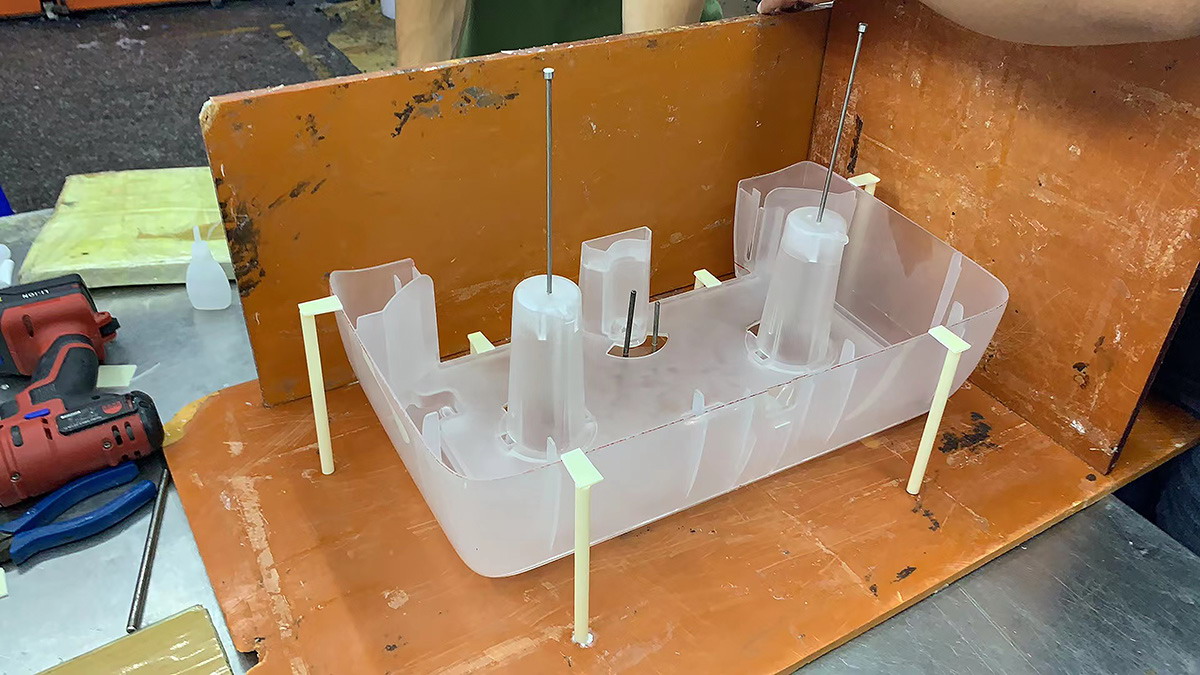

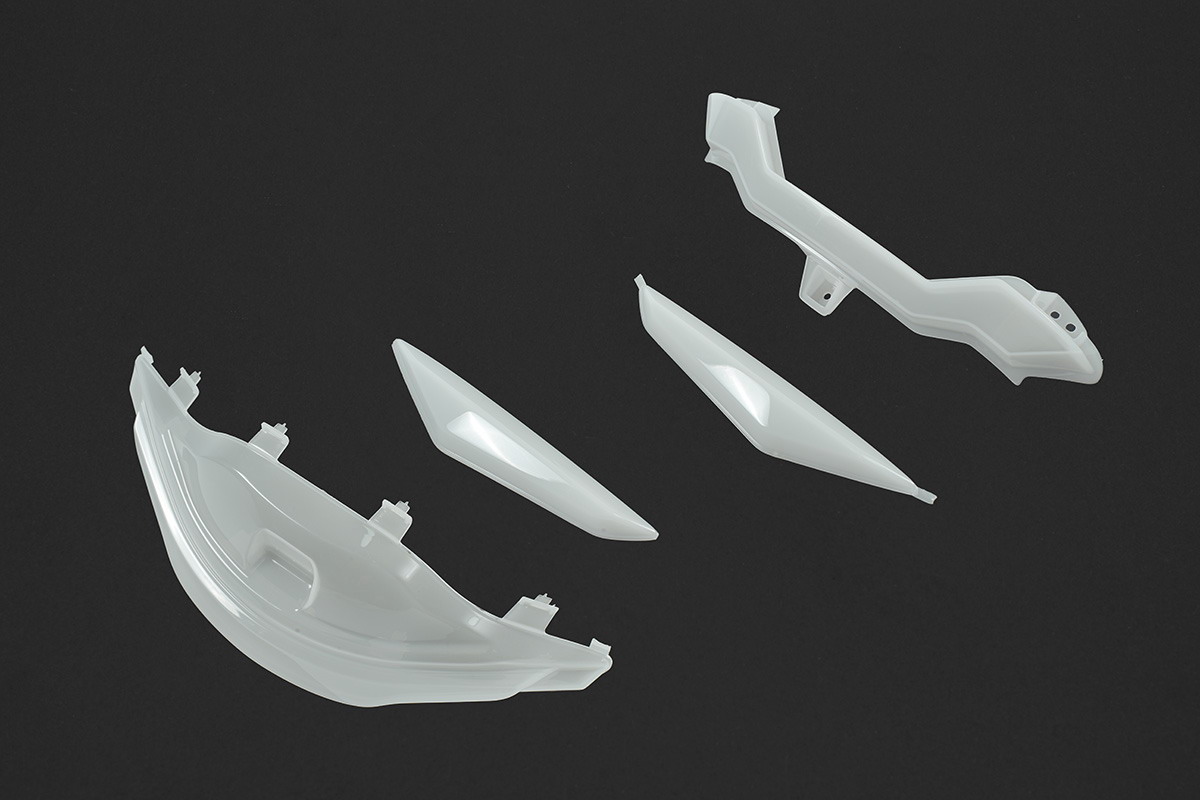

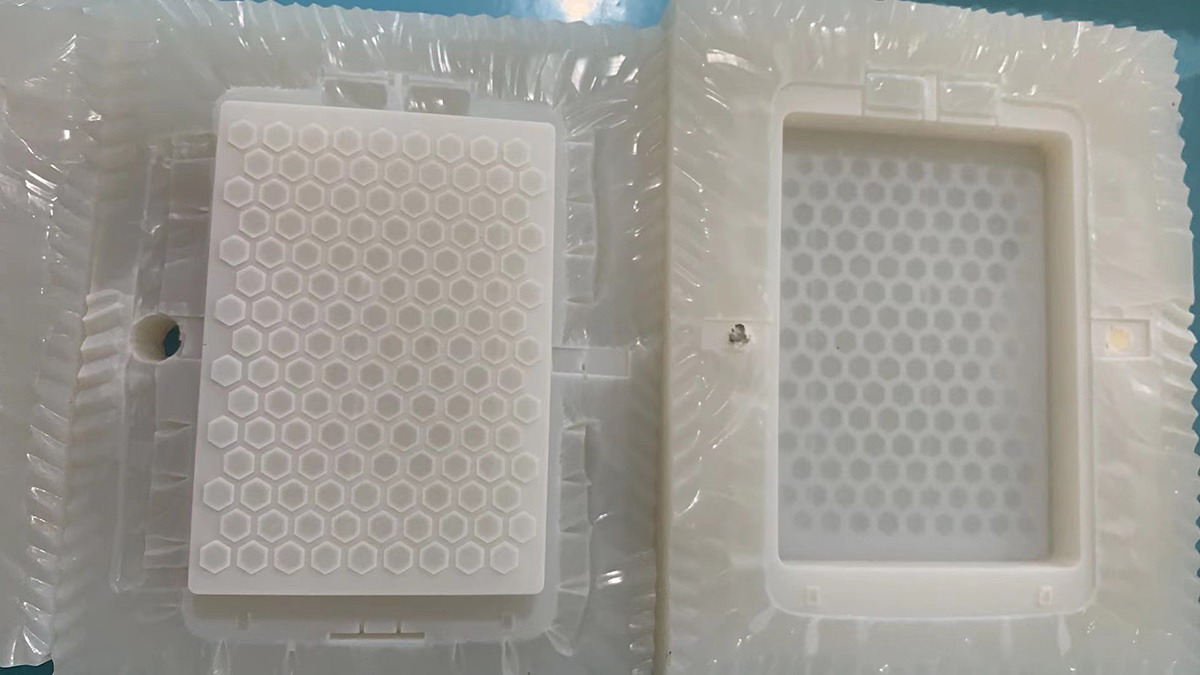

ZY Vacuum Casting Vacuum Casting, also called silicone mould, is a manufacturing process to make the mold in silicone from a master model, and then cast the parts out from polyurethane, transparent polyurethane, ABS and other materials under vacuum, to achieve the strength and hardness of ABS and other materials. The parts can be casted according to the color required by customers. Vacuum Casting is the best replacement of injection molding for low volume products. Casting material hardness and strength is very close to the injection molding material. Vacuum casting is a very low-cost and fast way to make prototypes if you want 20 to 100pcs of parts. |

Advantages of Vacuum Casting

➽ Fast turnaround: Usually 2 weeks or less to make parts ready ➽ Economical in both cost and time: Silicone molds are less expensive than metal tools, but more easier and faster to make ➽ large part making capacity: Very large parts can be produced shortly, supported by large vacuum casting machine | ➽ Surface finish options: Different Colors, Textures & Finishes Available ➽ Repeatability: Silicone molds can be used around 20 times before replacing. ➽ Excellent Physical Properties The casting parts have good Physical Properties for functional purpuse |

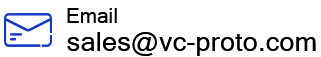

Casting Resin Material Available Casting resins are polymers with a wide range of properties and use. Zhiyou offers different kinds of casting resins materials to meet your applications, including Axson from France and Hei-Cast from Japan. Materials with certain properties are similar to engineering production plastics, such as ABS, PMMA, PC, PP, PA, etc. Some special materials are also available, like high-temperature resistant (120℃ or 200℃) or fire-resistant (UL94-V0). |

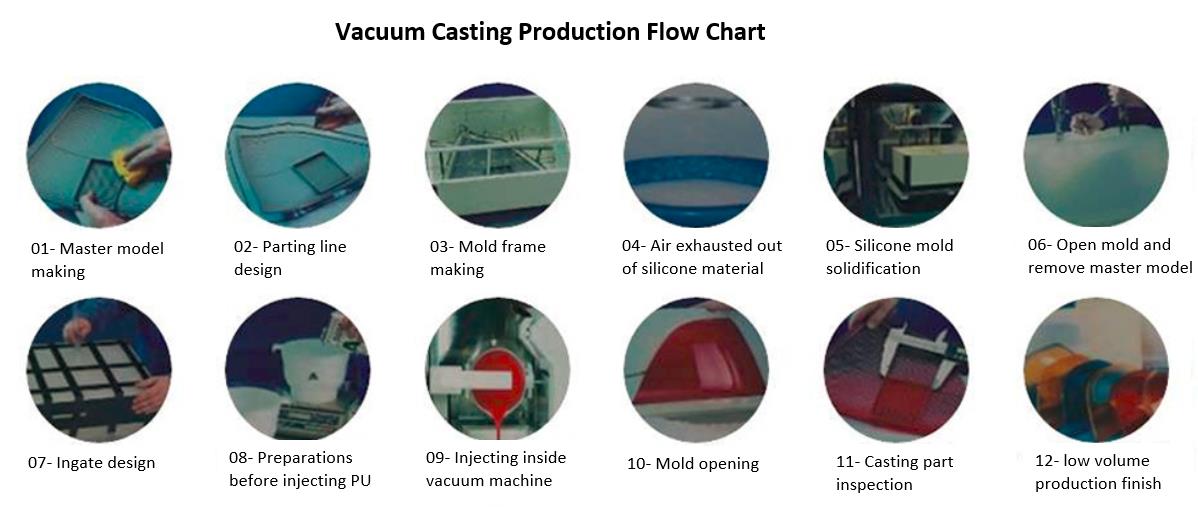

How It Works (3 steps)

Step 1. Master model building– CNC machined or 3D printed via SLA or SLS

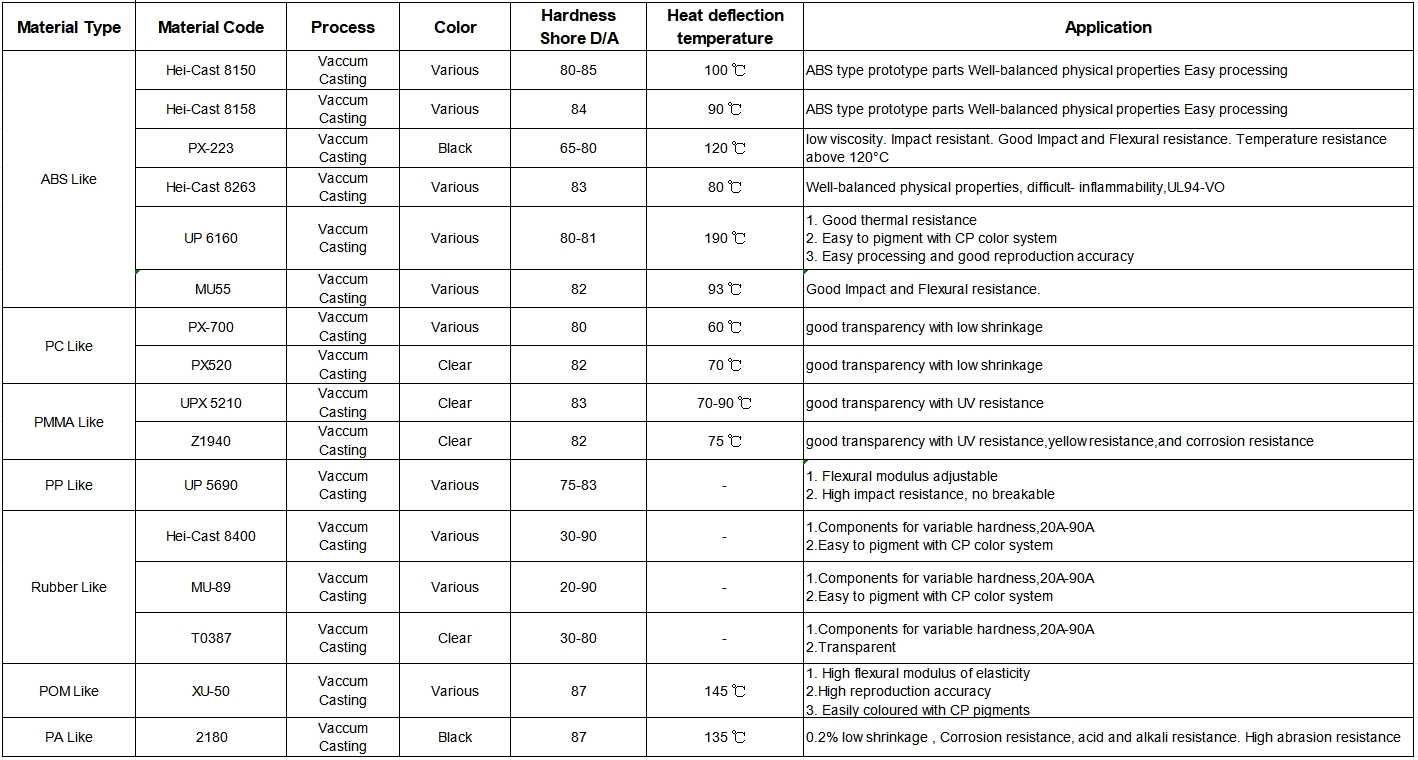

Step 2. Silicone mold making – liquid silicone is poured around the master model and fully cured. Once dried, the mold is cut open and master is removed

Step 3. Casting parts – the casting resin is poured into the cavity to create products, like replicate

Detailed step as below

GET A QUOTE ONLINE

Professional rapid prototyping partner to save your cost and time