Our Quality Control Process

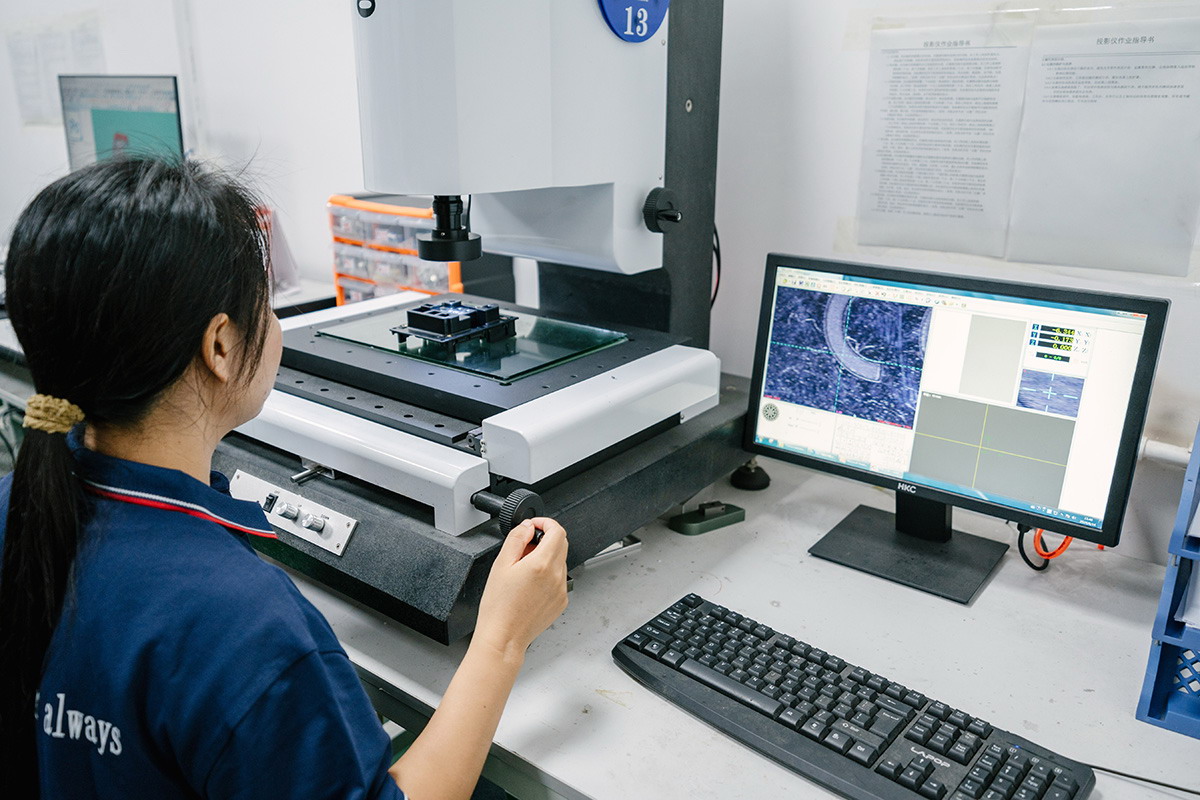

ZY company has a long-term quality assurance program and quality testing facilities to ensure our products meet high quality standard. With cutting-edge quality inspection technologies and testing equipments, we’re able to inspect the dimension, hardness, tensile strength and so on during whole manufacturing process.

Incoming Quality Control All raw materials or semi-finished parts are obtained from carefully selected suppliers, and will be go through extensive quality inspection before being stored or processed. |

|

| In-process Quality Control FAI(first article inspection)will be performed and recorded during IPQC. We focuses on appearance and critical dimensions at each stage of production. ● Appearance Check |

|

|

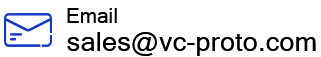

| Quality Inspection Equipments ● SEREIN Croma Coordinate Measuring Machine (CMM) |

GET A QUOTE ONLINE

Professional rapid prototyping partner to save your cost and time